16

CUTTING-OFF

& GRINDING

WHEELS

TECHNICAL INFORMATION

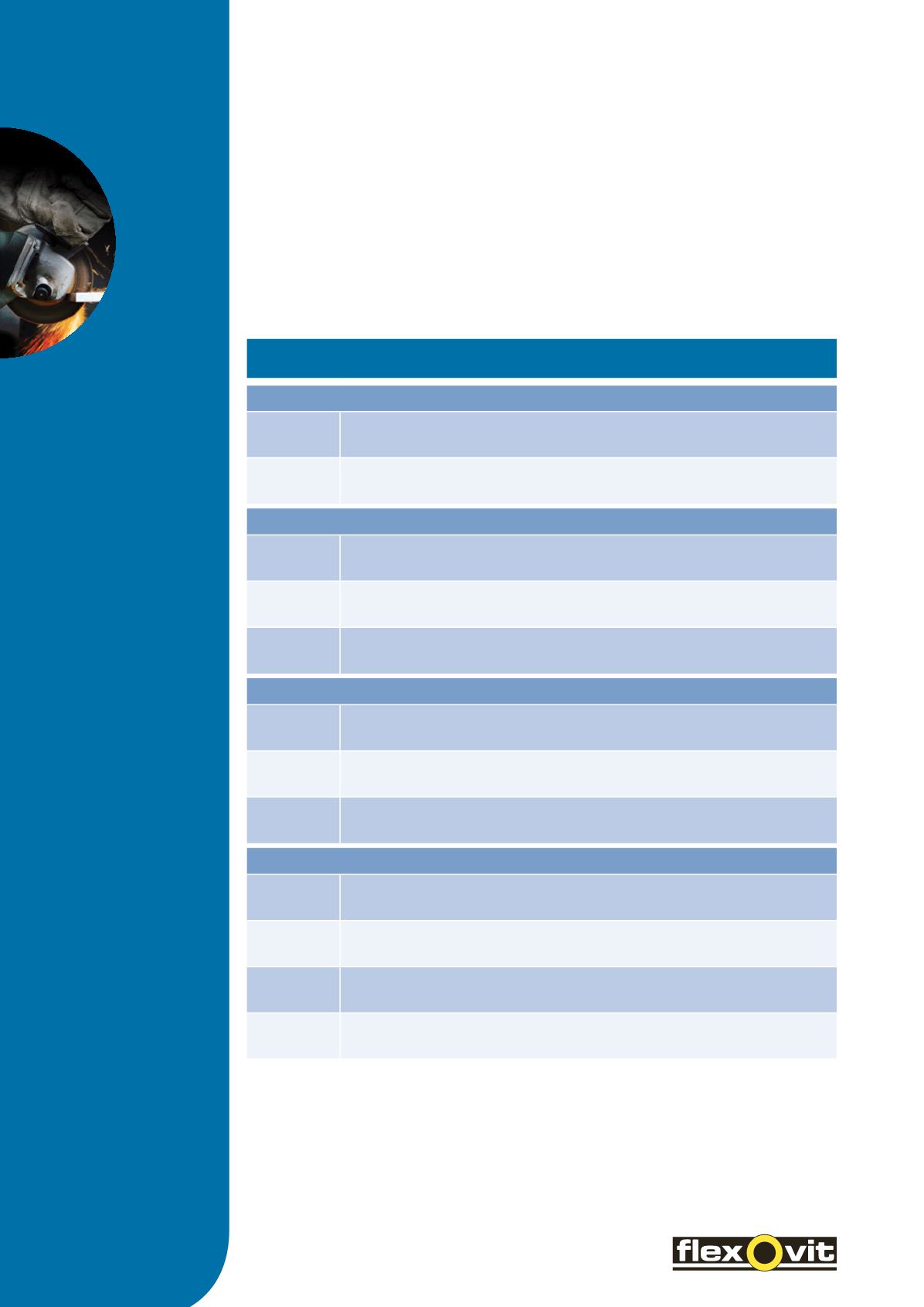

TROUBLESHOOTING CUTTING OFF WHEELS

Wheel does not cut

Cause

Solution

in case of blue cutting: wheel too hard or too thick use softer or Flexovit Thin Cut wheels,

check peripheral speed

Cause

Solution

peripheral speed too low

increase rpm up to max. (80m/s)

Excessive wear

Cause

Solution

in case of white cutting edge: wheel too soft

use harder wheel

Cause

Solution

operating speed too low

increase rpm up to max (80m/s)

Cause

Solution

decrease of rpm during cutting

use machine with more power, reduce pressure on the machine

Crumbled wheel edge

Cause

Solution

cutting-off wheel used for grinding operations

use a grinding wheel for grinding operations

Cause

Solution

workpiece is moving

clamp the workpiece properly

Cause

Solution

too much side-pressure

add only the radial pressure to the wheel

Arborhole or centre break out

Cause

Solution

wheel sticks in the workpiece/material

use more radial pressure and swing the wheel forwards and backwards

Cause

Solution

cutting-off wheel used for grinding operations

use a grinding wheel for grinding operations

Cause

Solution

too much side pressure

add only the radial pressure to the wheel

Cause

Solution

different diameter top/bottom flange

use flanges with the same diameter

GETTING THE BEST FROM YOUR CUTTING-OFF

& GRINDING WHEELS

• Decide which material is cut most and that you select the most suitable Flexovit wheel in accordance

with the application chart in this chapter. To use the right wheel for the right material is very important

for the life and cutting/grinding behaviour of the wheel

• Check if the machine is operating correctly and that the machine does not exceed the speed that is indicated

on the wheel

• Use the wheel at the recommended speed indicated on the wheel and the maximum operating speed chart

that you will find later in this chapter

The troubleshooting guide can easily help you recognise and solve problems.