COATED

ABRASIVES

114

Manufactured with abrasive cloth edges radially arranged about a core, flap wheels are one of the most

commonly used abrasive tools. They are particularly suited to roughing, smoothing, and polishing operations

on materials such as iron, brass, wood, and synthetic materials, they can be mounted on electrical and pneumatic

portable machines or on fixed machines such as grinders, polishers.

The wheels may also be used for specialised wet machining applications and may be shaped for special workpieces.

FLANGE MOUNTED FLAP WHEELS

PREPARATION BEFORE USE

Flange mounted flap wheels must only be used on machines specifically manufactured for this purpose.

Always use the mounting flanges supplied by the wheel manufacturer. Ensure that the wheels are mounted strictly

in accordance with the manufacturer’s instructions. Ensure that the wheel is centrally and securely mounted

on the machine and that it runs in the same direction as the arrow marked on it. Check that the maximum

operating speed of the wheel, given in RPM, is higher than or equal to the spindle speed of the machine.

Never exceed the maximum operating speed recommended by the manufacturer.

PERSONAL PROTECTION

Safety goggles, ear defenders, safety gloves, dust masks and, if grinding conditions are severe, additional face

protection, leather aprons and safety shoes must be worn.

FLAP WHEELS

STORAGE

Flap wheels should be stored in accordance with the recommendations given and should be stored flat or hung

on their spindles to avoid permanent deformation.

MAXIMUM OPERATING SPEED

Diameter (mm)

Max RPM

100

8000

150

5800

165

5500

200

4500

250

3500

300

2800

350

2500

400

2200

PERSONAL PROTECTION

Mouth

Protection

Wear

Gloves

Eye

Protection

Ear

Protection

Read

Instruction

Dry

Wet

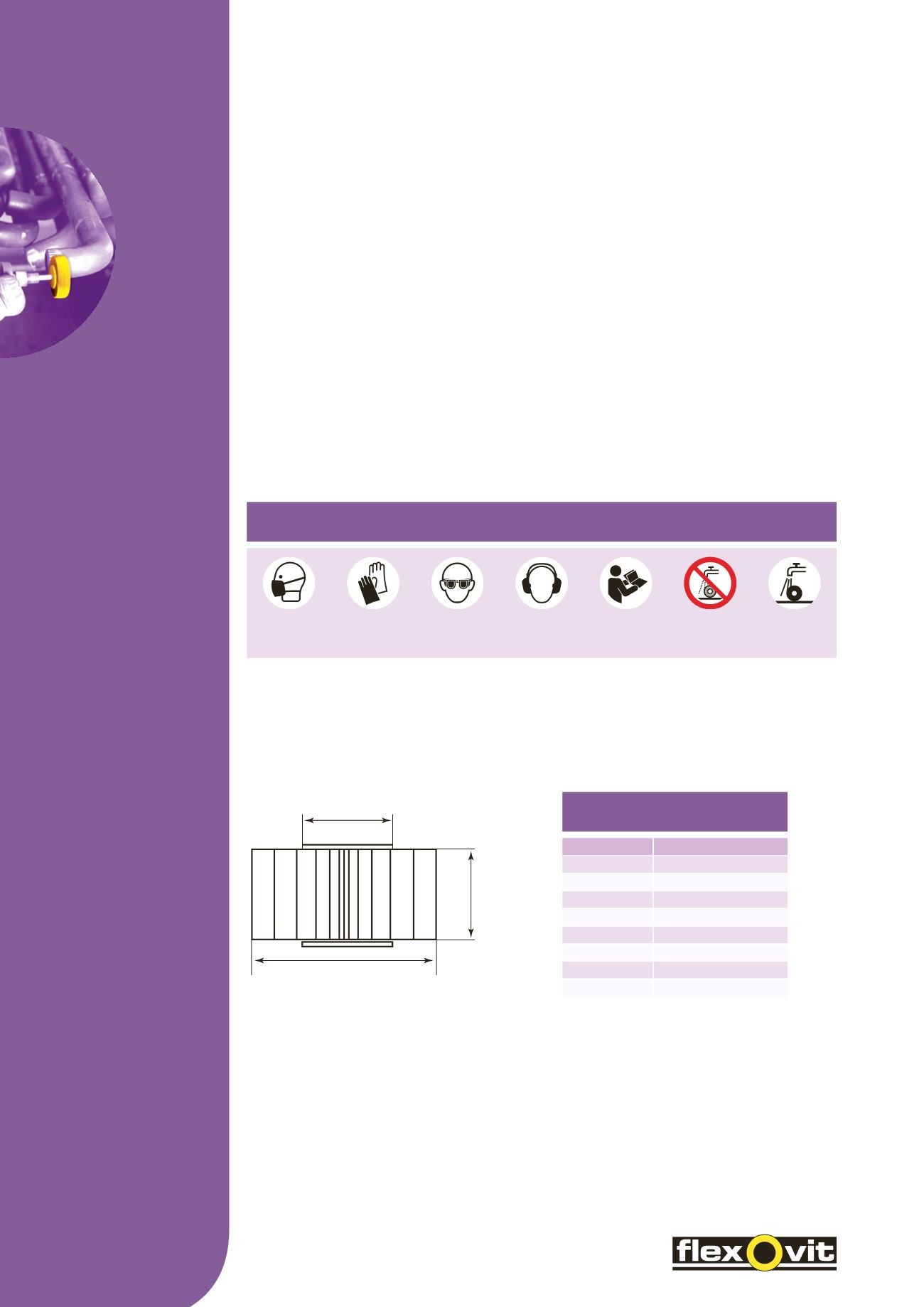

diameter

D

W

width

B

bore