COATED

ABRASIVES

116

FLAP WHEELS

CMYK

SGA

FlexovitSub-brand logo

Speedoflex_logo

N/A

11/08/2015

KX310

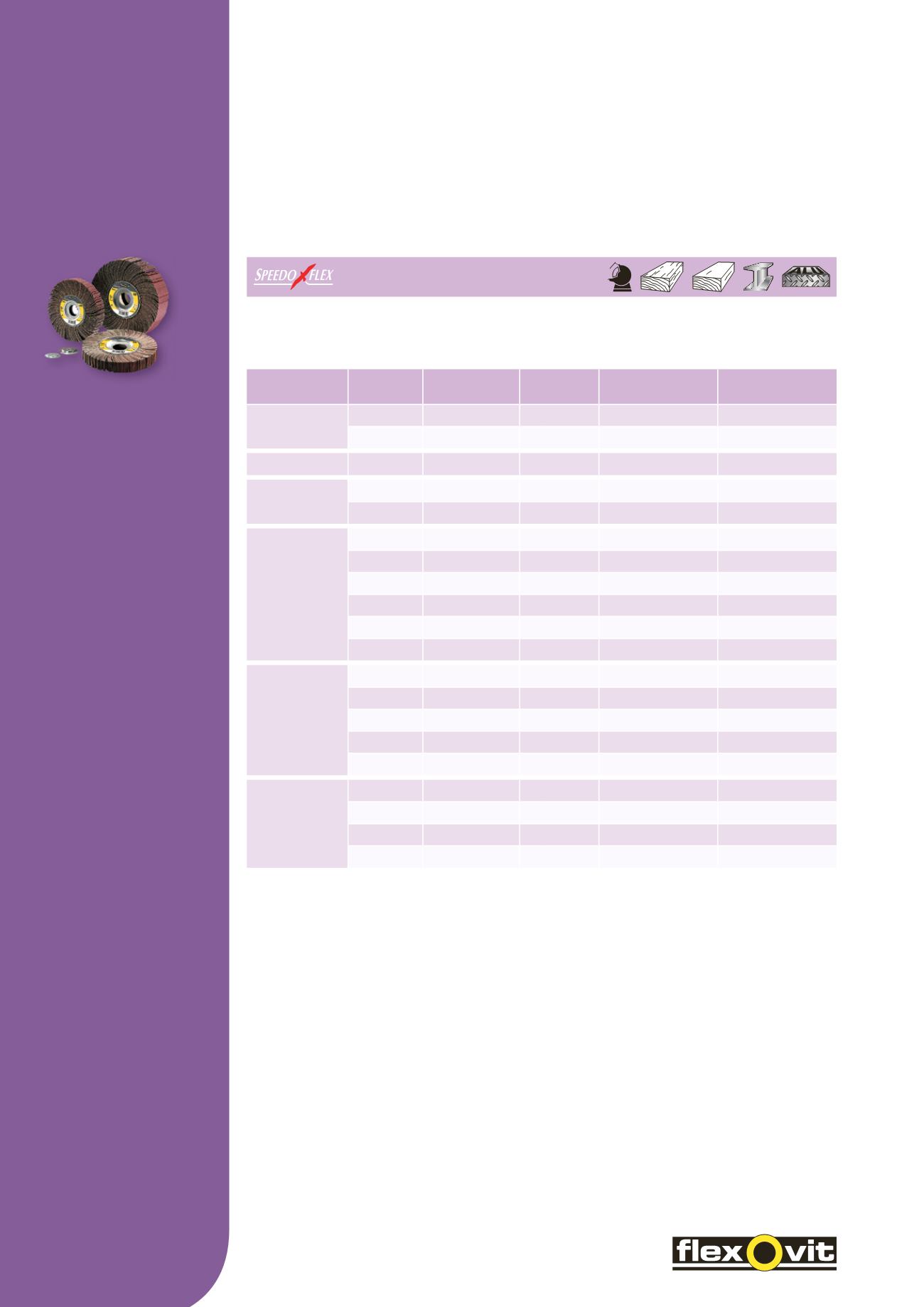

ALUMINIUM OXIDE FLAP WHEELS WITH FLANGES

• Cotton backing

• Comfortable, stable grinding

• Finishing

• Suited for curved surfaces, profiles and pipes

• For handheld and fixed machines

• Aluminium oxide abrasive suitable for use on steels,

nonferrous metals and wood

Dimensions

(mm) D x W x B

Grit

Recommend

speed (RPM)

Quantity

Article Number

Barcode

150 x 25 x 25

80

4800-5400

1

63642522337

8711479160431

120

4800-5400

1

66261162845

8711479160455

150 x 50 x 25

80

4800-5400

1

66261168474

8711479160486

165 x 25 x 30

60

4300-4900

1

66261168480*

8711479160530

120

4300-4900

1

63642524155*

8711479160561

165 x 30 x 30

40

4300-4900

1

63642585405*

3157625586864

60

4300-4900

1

63642585411

3157625586918

80

4300-4900

1

63642585413

3157625586925

100

4300-4900

1

63642585414*

3157625586932

120

4300-4900

1

63642585415

3157625586949

150

4300-4900

1

66261168492*

8711479160653

165 x 50 x 30

40

4300-4900

1

63642585416

3157625586956

60

4300-4900

1

63642585417

3157625586963

80

4300-4900

1

63642585418

3157625586987

100

4300-4900

1

63642585419

3157625586994

120

4300-4900

1

63642585420

3157625587007

200 x 50 x 30

60

3600-4000

1

63642585421

3157625587014

80

3600-4000

1

63642585423

3157625587021

100

3600-4000

1

63642585425*

3157625587038

120

3600-4000

1

63642585426*

3157625587045

* Made-to-order

See Accessories page for Reduction bushings

Flange mounted flap wheels achieve their best performance at a recommended speed of 38-42m/s. At this speed,

abrasive flaps stand up straight due to centrifugal force and only the edges are in contact with the workpiece, optimizing

stock removal, surface finish, and thermal load of the workpiece and toll wear.

Tip:

To prevent unnecessary tool wear do not increase too much the contact pressure, the increase of stock removal

should be achieved by using a coarser grit size. To get a slightly finer surface increase the cutting speed. To get a slightly

rougher finishing increase the contact pressure. Using same grit size, the finishing is rougher

on softer materials.