COATED

ABRASIVES

146

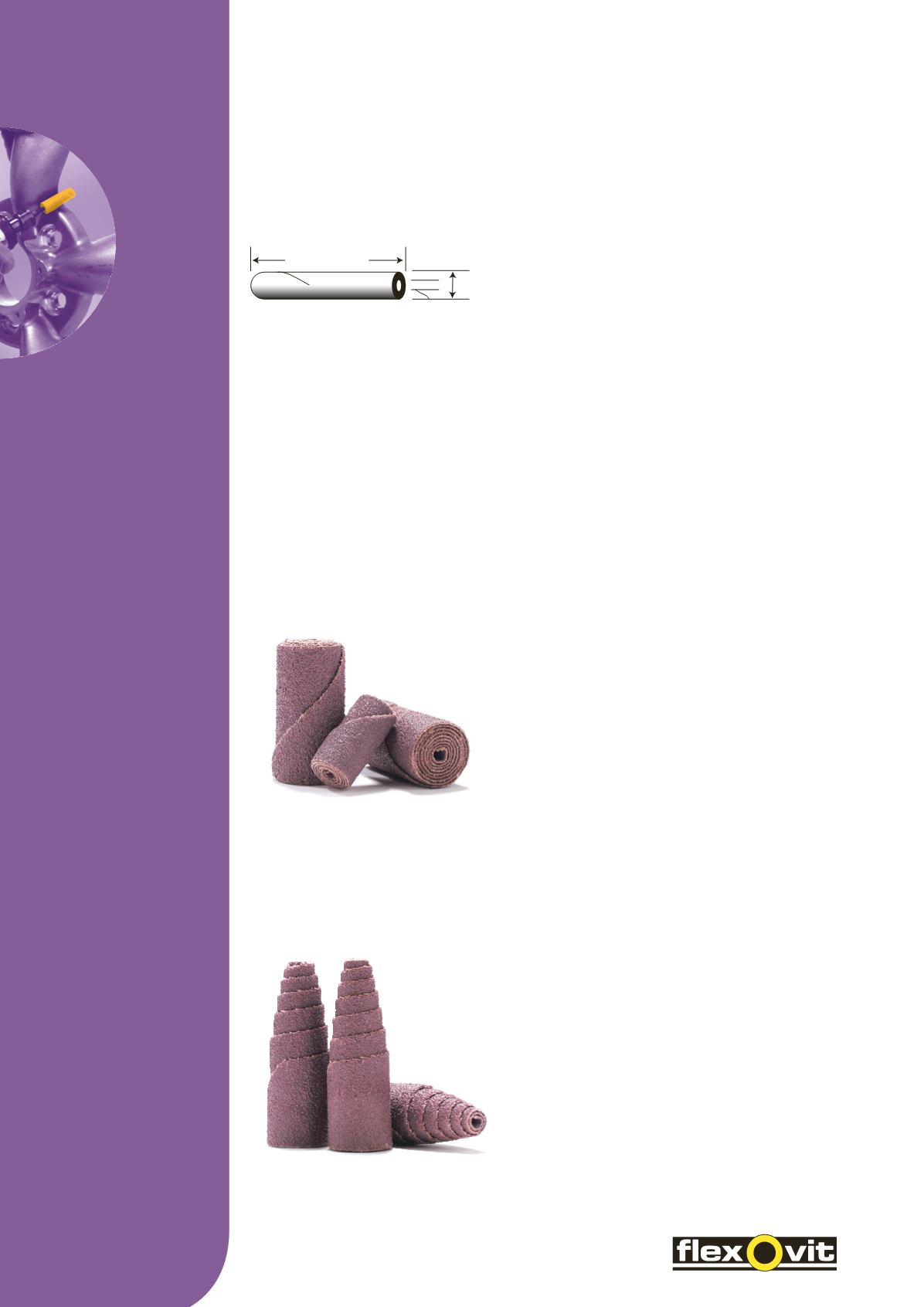

Cartridge Rolls are made up of rolls of Resin Bond Abrasive Cloth which allow a new cutting surface to be uncovered

as the top layer is worn away. They are available in 2 different shapes and in a wide variety of sizes and grades.

Cartridge Rolls are suitable for a range of applications including flash removal, polishing, edge breaking and

removing machine tool marks. They are also especially good for reaching into corners. They are available in

Aluminum Oxide – with a resin bond and also to special order in Silicon Carbide or Ceramic. Many operations

use straight cartridge and spiral rolls together They are more flexible than a bonded mounted point and cause

less chatter marks than a spiraband.

ALUMINIUM OXIDE STRAIGHT CARTRIDGE ROLLS – ZPE ALOX

• Straight with no taper. Most popular

• Wears to shape required

• For sanding and polishing channels, fillets, recesses, side walls and bottoms of dead-end holes

• Metal channels

• Fillets

• Recesses

• Contours

• Bottoms of dead end holes

• Removing parting lines, imperfections and burrs

• Deburring stampings and dies

• Corners

• Tight radii

• Angles

CARTRIDGE ROLLS

ALUMINIUM OXIDE TAPERED CARTRIDGE ROLLS – ZSPI ALOX

• Taper from tip to base

• Particularly adaptable to grinding/polishing of channels, fillets, radii and small contours of metal parts

L = Length

Ba =

Base

B = Bore