FLEXBRITE

NON-WOVEN

ABRASIVES

187

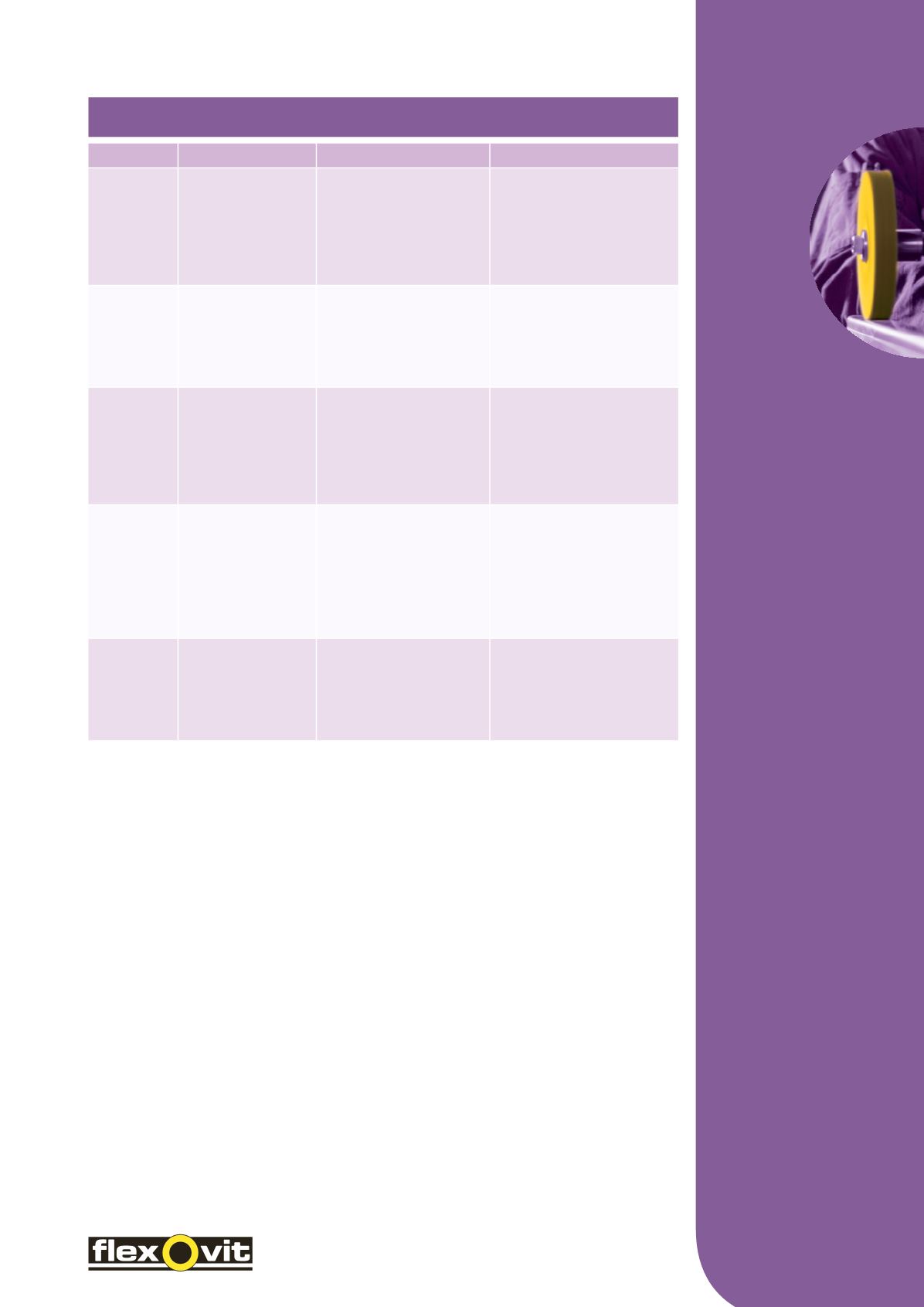

APPLICATION CONVOLUTE WHEELS

Type

Features

Benefits

Application

Clean Finish

wheels (DCS) –

fine Finish with

light pressure

Open mesh construction,

Silicon Carbide Grain

Used with light to moderate

pressure, low speed. Good for

blending, rust removal, applying

decorative contrast finishes

and low to moderate speed

applications. Not used

for deburring

Blending weld areas on stainless

steel to #4 finish. Removing rust

and oxides. Applying decorative

contrast finishes. General clean-up

Surface

Finishing

Wheels (DSS)

uniform finish

with moderate

pressure

Stronger web compared

to Clean / Finish wheels

More aggressive cutting action

& more durability than Clean /

Finish wheels. Ideal for rust and

paint removal, coarse decorative

finishes, and blending

Removing rust and paint. Applying

coarse decorative finishes.

Blending to a higher degree.

General clean-up

Metal Finishing

Wheels (DMA)

Blending & final

finishing

Strongest resin binders.

Dense, very durable web.

Premium, medium grit

aluminium oxide grain.

Uniform grain dispersion

and coating

Resilient long life construction.

Can be used for light deburring-

applications. Generates uniform

distinct satin and antique finishes.

Cleans and conditions without

gouging or changing dimensions

of workpiece

Blend and match #3 or #4 mill

finishes. Generate the uniform

appearance required for decorative

finishing. Prepare a surface for

buffing or polishing. For blending

or finishing operations

SERIES 1000

Wheels (D1S/A)

General

deburring,

blending &

finishing

Smear and heat resistant

formula.Waterproof Non

metallic. Dense

web construction

(9 density). More open

web construction

(6 density)

Use dry, wet or with oil. No

contamination of workpiece.

Long life & consistent high

quality results. Starting point for

deburring, blending polishing

and finishing. Smear proof &

cool cutting on light deburring

applications

General Deburring. Blending coated

abrasive scratch patterns. Polishing

stainless steel cutlery, golf clubs

and computer parts. Deburring

and finishing intricate shapes.

Centreless polishing.

Glass polishing. Edge radiusing

SERIES 4000

Wheels

(D4S/A) Heavy

deburring

applications

Improved resin bond

system. High quality

synthetic web. Smear

& heat resistant. Premium

abrasive grain.

Free cutting – Use both wet

and dry. More consistent finish.

Better performance. Long life for

heavy deburring, edge breaking

& removing parting lines on

exotic metals

The choice where edge and form

holding are of primary importance.

Ideal for heavy duty deburring, edge

breaking and parting line removal

on metals for all sharp, narrow

point of contract applications