FLEXBRITE

NON-WOVEN

ABRASIVES

183

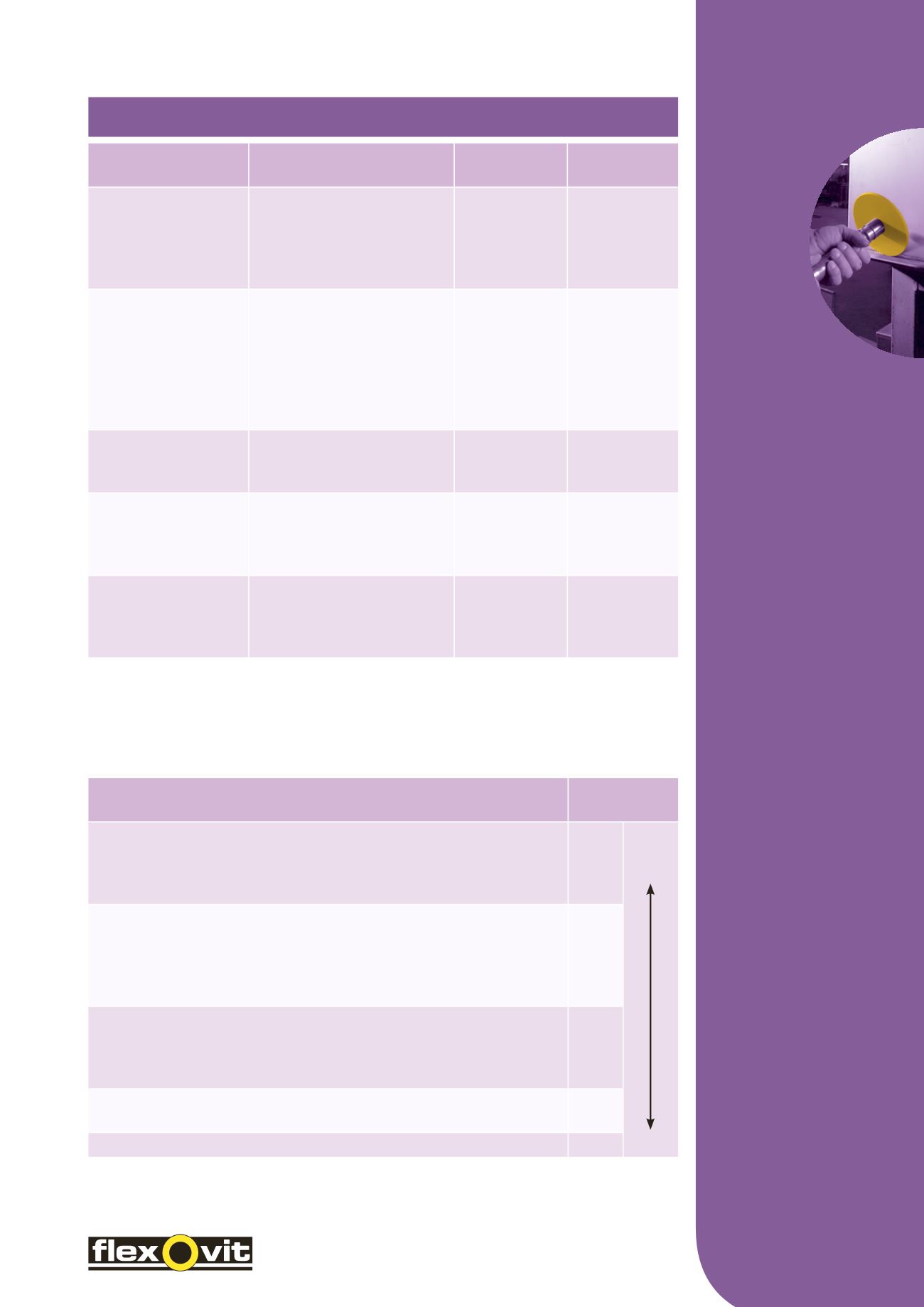

SELECTING THE RIGHT PRODUCT

Application Area

Specific Application

Specification

Recommended

Speeds

Cleaning:

Oxidation removal,

coatings, contaminants

Welding preparation /Removal

of weld blueing / Scale Removal

/ Gasket removal / Removing

excessive bonding agents after

curing / Cleaning steel castings

NEX 4AFINE, 6AF

8AMED

10-26m/s

De-Burring:

Surface, edge, & thread

de-burring

De-burring flashings, threaded

parts, stamped parts, turbine

blades, machined out parts /

De-burr

aluminium extrusions /

De-burring pipes in the oil and

gas industry

NEX 2SFINE,

4AFINE

10-26m/s

Blending:

Removal parting lines,

grindline conditioning

Parting line removal / Blending

surface defects and

forge marks

NEX 8MED,

8ACOARSE

30-40m/s

Finishing:

Final finishing, satin

finishing

Turbine blade edge radius /

Medical implants (stainless steel

and alloys) / Figurines / Jewellery

/ Finishing saw blades

NEX 6AF, 8AM 2/5-15m/s

Polishing:

Polishing surface defects,

surface preparation

before buffing

Polishing precision metal pieces,

welds etc.

NEX 2SFINE,

8AFINE

2/5-15m/s

Unitized Wheels can be run in either direction

Tools – Machinery according to diameter and application

Angle Grinder/MiniGrinder/Air/Electric (25mm to 125mm - 1" to 5") Straight Shaft/Flexi Shaft/Die Grinder 25mm to 150mm

(1" to 6")

Bench Motor Pedestal Grinder 100 to 203 (4" to 8")

Application

Choose

Density

• Light cleaning (lacquers, welding colours)

• Removal of corrosion and scratches

• Blending

• Polishing

2

soft

• Cleaning

• Surface blending

• Removal of scratches

• Polishing after weld removal

• Pre-polishing

4

• De-burring

• Removal of grinding scratches (G 80 on steel, G 120 on aluminium)

• Edge breaking

• Heavy cleaning

6

• Heavy de-burring

• Weld seam removal

8

• De- burring on very hard material

9

hard