DIAMOND

BLADES

210

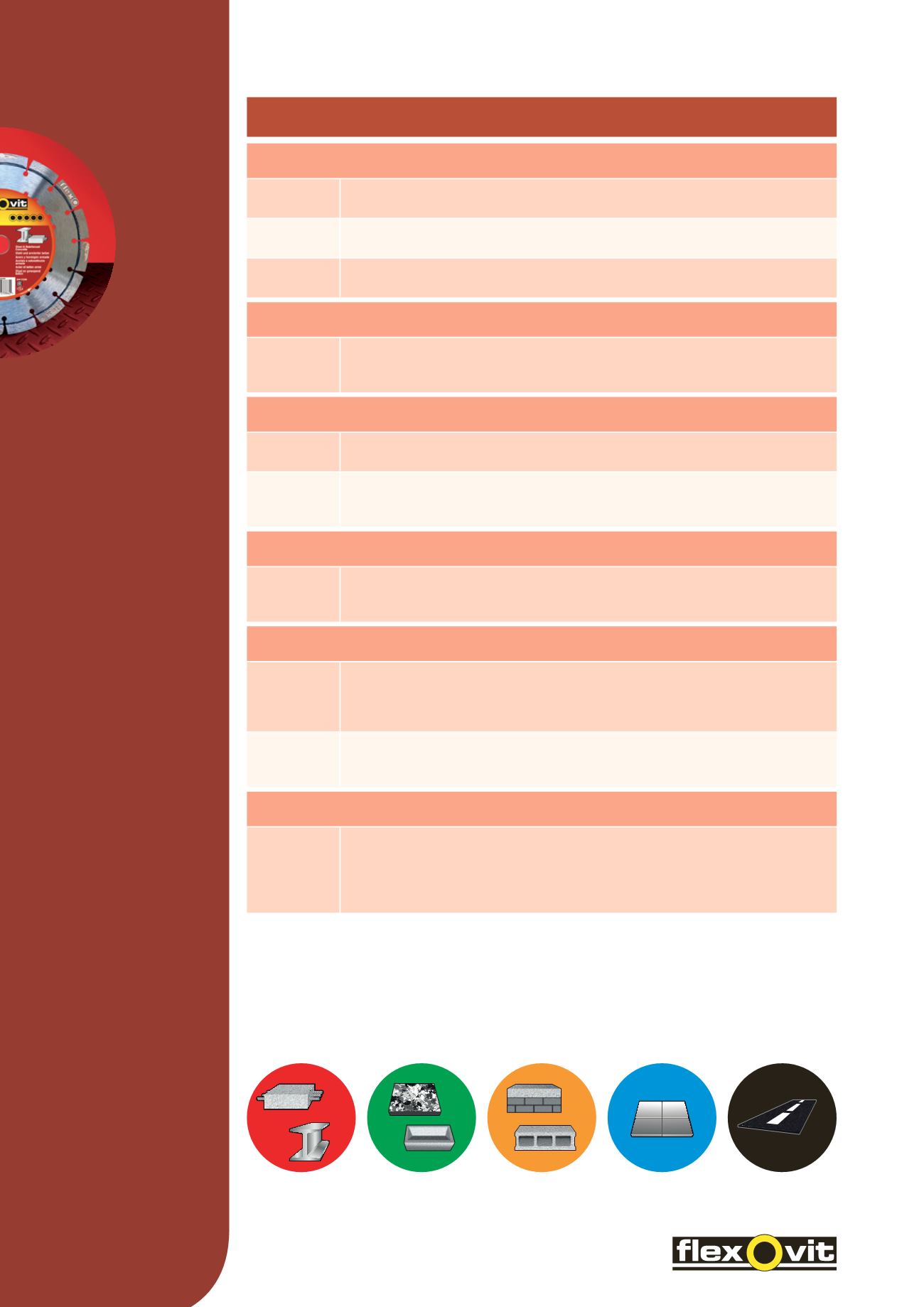

TECHNICAL INFORMATION

APPLICATION COLOUR CODES

TROUBLESHOOTING

DIAMOND BLADE DOES NOT CUT

Cause

The segments are too hard for the material

Solution

Check if the blade is suitable for the material

Cause

The segments have become blunt

Solution

Sharpen the segments by cutting an abrasive material (e.g. sandstone)

Cause

Insufficient machine power

Solution

Check the voltage, machine power and filters

EXCESSIVE WEAR

Cause

The segment is too soft for the material (e.g. if a blade for hard material is used to cut

abrasive material)

Solution

Check if the diamond blade is suitable for the material

CRACKING OF STEEL CENTRE

Cause

The segments are too hard for the material

Solution

Check if the blade is suitable for the material

Cause

Excessive cutting pressure, overheating, material slippage, twisting or jamming in the cut

Solution

Leave the blade to do the work, do not exert too much pressure and allow the blade

to cool regularly by leaving it to rotate away from the workpiece for a few seconds

LOOSENING OR CRACKING OF SEGMENTS

Cause

The segments are too hard for the material. This results in the diamond blade bouncing in the cut

resulting in cracking segments

Solution

Check if the diamond blade is suitable for the material

SCORCHING OF SEGMENTS

Cause

Excessive cutting pressure causing overheating. This is easily recognisable from the blue colouring

where the segments and the steel core are welded together

Solution

Allow the diamond blade to cool regularly by rotating the blade away from the workpiece for a few

seconds

Cause

The segments are too hard for the material

Solution

Check if the diamond blade is suitable for the material. Alternatively use less cutting pressure

and let the blade do the work

UNDERCUTTING

Cause

Undercutting occurs when the steel core wears faster than the segment, i.e. where the segment

and steel core meet. This is usually caused by materials that are highly abrasive. The cutting

debris is not removed sufficiently and the steel core is affected. Undercutting is certain to occur

if a diamond blade for hard materials is used to cut abrasive materials

Solution

Use a diamond blade suitable for the specific material

Steel/Reinforced

Concrete

General Purpose/

Granite

Asphalt/Abrasive

Materials

Concrete/

Hard Materials

Tile

Brick&concrete

Concrete

Metal&conrete

Asphelt

Brick

Aliminium

Aluminium2

Granite

CeramicTiles

Inox

Anglegrinder

Handheldpetrol saw

Floor saw

Masonry saw

Steel

Cast Iron

Tilecutter

Stone

Brick&concrete

Concrete

Metal&conrete

Asphelt

Brick

Aliminium

Aluminium2

Granite

CeramicTiles

Inox

Anglegrinder

Handheldpetrol saw

Floor saw

Masonry saw

Steel

Cast Iron

Tilecutter

Stone

Brick&concrete

Concrete

Metal&conrete

Asphelt

Brick

Aliminium

Aluminium2

Granite

CeramicTiles

Inox

Anglegrinder

Handheldpetrol saw

Floor saw

Masonry saw

Steel

Cast Iron

Tilecutter

Stone

Brick&concrete

Concrete

Metal&conrete

Asphelt

Brick

Aliminium

Aluminium2

Granite

CeramicTiles

Inox

Anglegrinder

Handheldpetrol saw

Floor saw

Masonry saw

Steel

Cast Iron

Tilecutter

Stone

Brick&concrete

Concrete

Metal&conrete

Asphelt

Brick

Aliminium

Aluminium2

Granite

CeramicTiles

Inox

Anglegrinder

Handheldpetrol saw

Floor saw

Masonry saw

Steel

Cast Iron

Tilecutter

Stone

Brick&concrete

Concrete

Metal&conrete

Asphelt

Brick

Aliminium

Aluminium2

Granite

CeramicTiles

Inox

Steel

Cast Iron

Stone

Brick&concrete

Concrete

Metal&conrete

Asphelt

Brick

Aliminium

Aluminium2

Granite

CeramicTiles

Inox

Steel

Cast Iron

Stone

Brick&concrete

Concrete

Metal&conrete

Asphelt

Brick

Aliminium

Aluminium2

Granite

CeramicTiles

Inox

Anglegrinder

Handheldpetrol saw

Floor saw

Masonry saw

Steel

Cast Iron

Tilecutter

Stone