CARBIDE BURRS

AND STEEL

BRUSHES

266

TUNGSTEN CARBIDE BURRS

Flexovit tungsten carbide burrs are manufactured on state of the art CNC machines to give high consistency

and quality. All Flexovit tungsten carbide burrs feature fast stock removal and long service life, providing optimum

efficiency. With the right choice of fluting style and speed, the carbide burrs can be used to grind and finish the most

diverse types of material, such as:

CUT STYLES STANDARD AVAILABLE

DC Double cut (worldwide most

standard product)

DC/

HD

Double cut/heavy duty. Negative

rake, extra strong tooth formation

for reduced chipping and longer

toollife

ALU Aluminium

FD Fine diamond cut

SHAPE

A Cylinder

H Flame

B Cylinder with end cut

J Countersink 60°

C Ball nosed cylinder

K Countersink 90°

D Ball

L Ball nosed cone

E Oval

M Cone

F Ball nosed tree

N Interverted Cone

G Tree

RIM

Aluminium

Brass

Titanium alloys

Cast Iron

Copper

Zinc alloys

Alloy steel

Bronze

Plastic

Nickel

Stainless steel

Carbide burrs can be used with both electrically-powered and pneumatically-powered hand-held grinders.

Each carbide burr is packed individually in a plastic case.

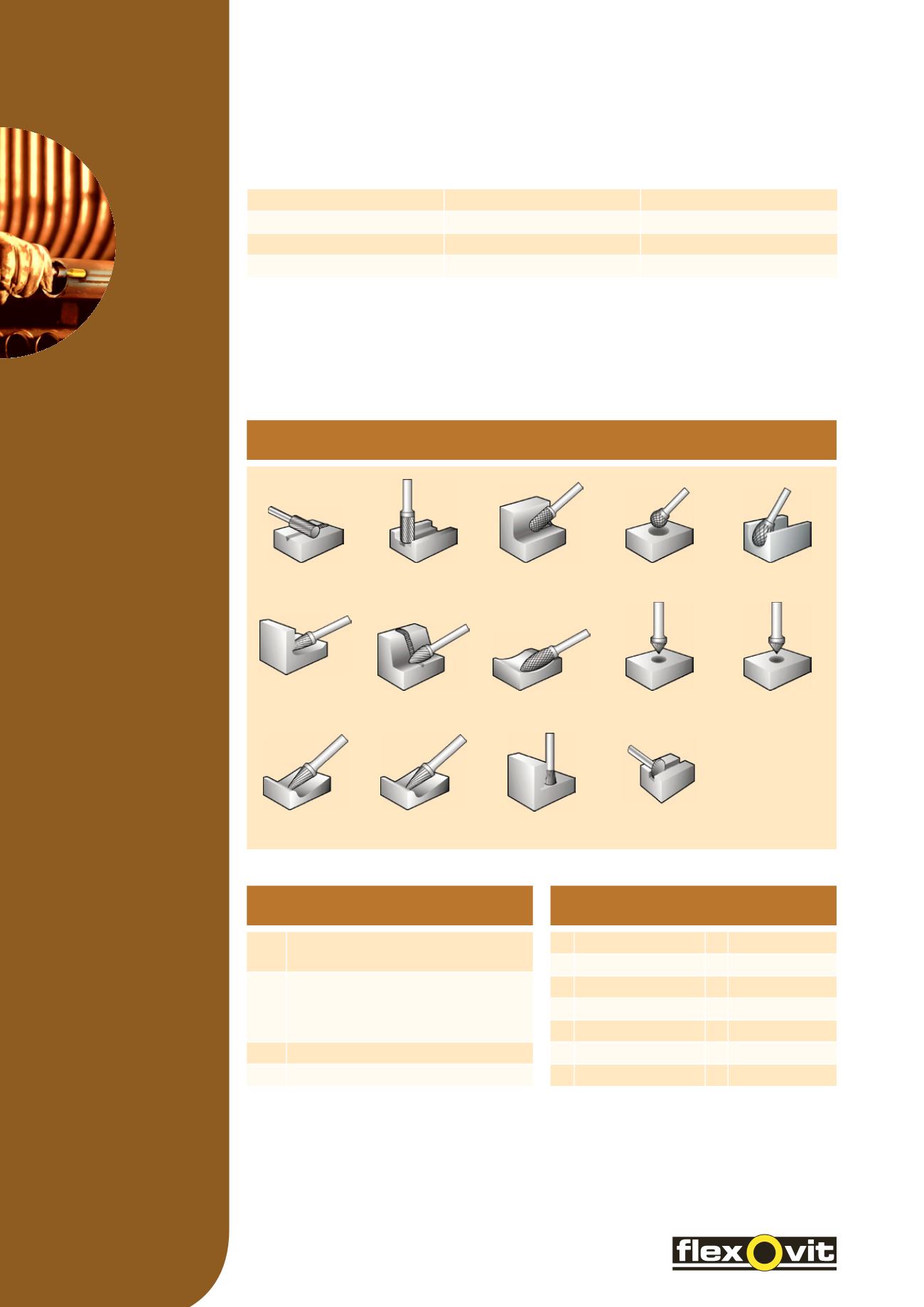

UNDERSTANDING THE PRODUCT

APPLICATION BY SHAPE

A.

Cylinder

B.

Cylinder with end cut

C.

Ball nosed

cylinder

D.

Ball

E.

Oval

F.

Ball nosed tree

G.

Tree

H.

Flame

J.

Countersink 60°

K.

Countersink 90°

L.

Ball nosed cone

M.

Cone

N.

Inverted cone

RIM