CARBIDE BURRS

AND STEEL

BRUSHES

268

Availability Standard

Standard

Standard

Standard Make to order Make to order

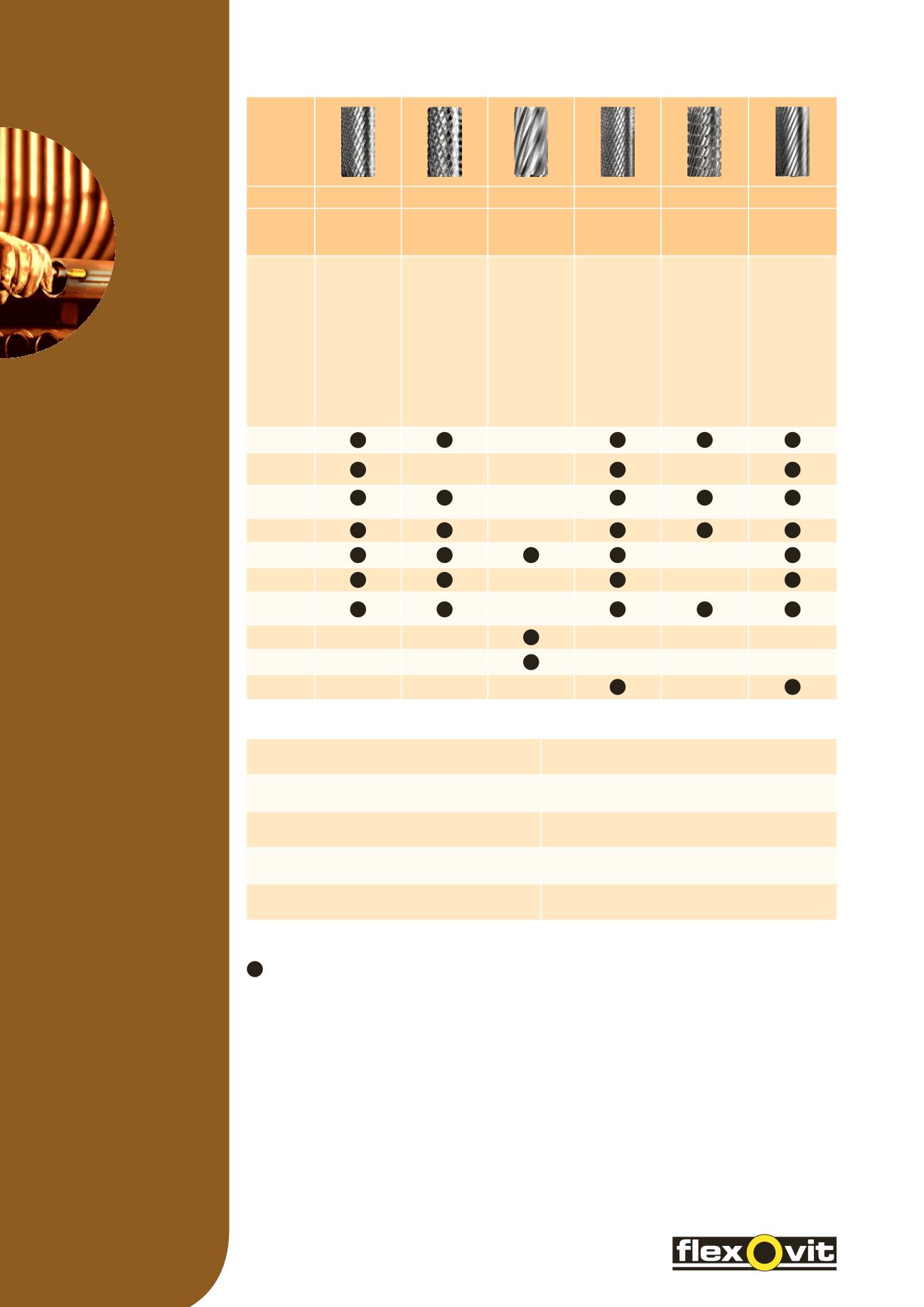

Cutstyle

DC Double

cut

DC/HD

Double cut

heavy duty

ALU

Aluminium

cut

FD

(fine diamond)

CD cut (coarse)

PC

plain cut

Qualities

Universal

cutting style

Fast material

removal

Smooth finish

Granular chip

break

Better stock

removal

Stronger tooth

formation

(decreased tooth

wedge angle)

Longer tool life

Reduced

chipping

For deburring of

aluminium alloys

and plastic

Wide tooth

formation Easy

chip flow

Granular chip

break

Fine finish

applications

Use on heat

treated and

tough alloy steel

General purpose

deburring

General

purpose

application

Produces

scratch free

surface

Steel

Hardened

Steel

Stainless

Steel

Cast Iron

Titanium

Nickel

Copper/

Copper alloys

Aluminium

Plastics

Cement

SELECTING THE RIGHT PRODUCT

It may be necessary to adjust the rates shown

to achieve optimum performance

Running below the optimum speed

will encourage chipping

Harder materials require slower speeds

Running above optimum speed

will cause tooth wear

Smaller burrs require faster speeds

Allowing the tool to become too hot may cause the braze

to melt and detach the head of the shank

Extra long burrs (>150mm long) require slower speeds.

(Max. 15000 RPM)

Using tools and collets that have become

worn will encourage chipping

Apply constant movement and light pressure

when in use

Do not sink the burr for more than

one third of its periphery

USAGE KEY

recommended