CARBIDE BURRS

AND STEEL

BRUSHES

286

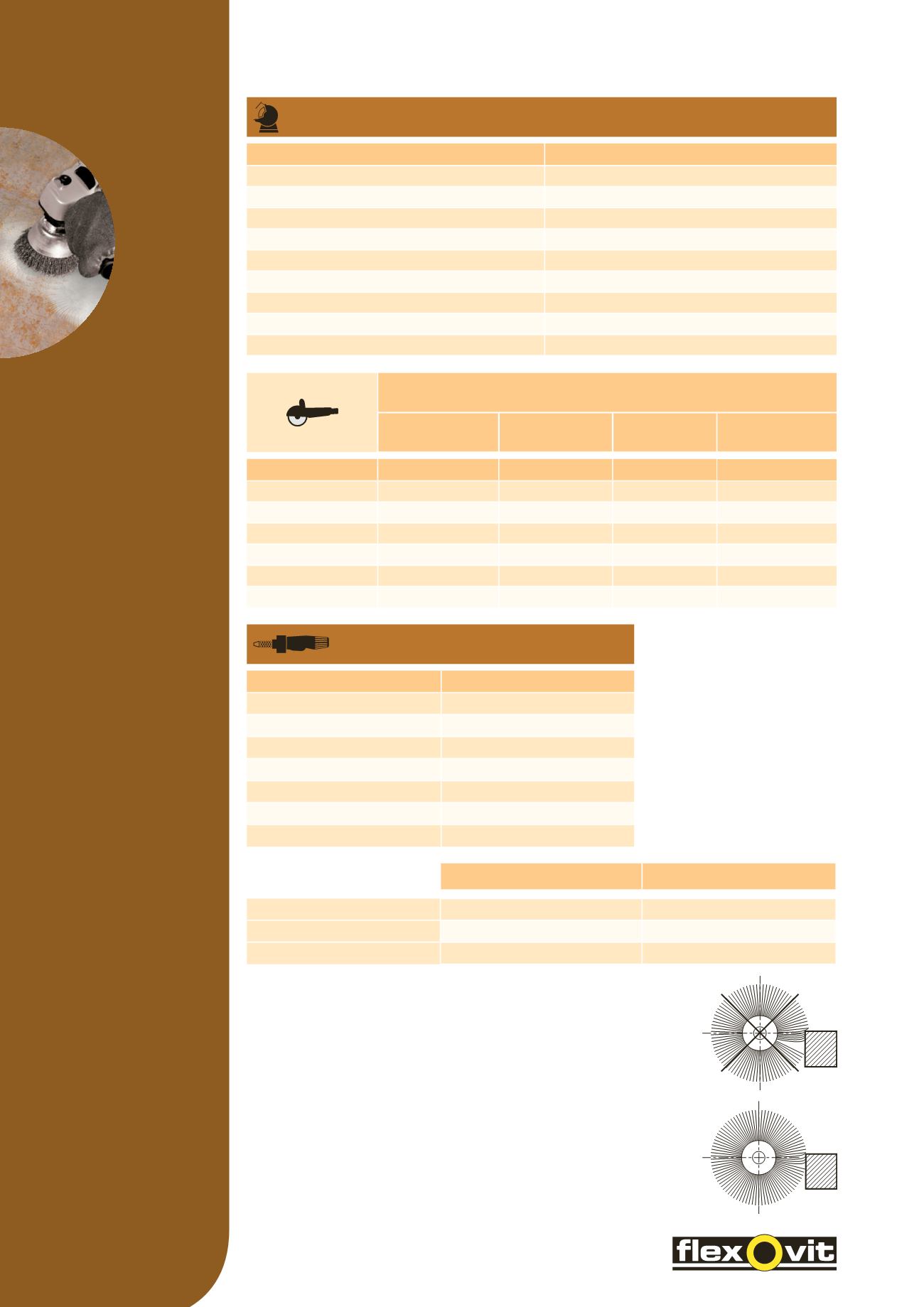

TECHNICAL INFORMATION

BORSTEL TYPE

Max Peripheral speed

of the machine

CUP BRUSHES BEVEL BRUSHES

TWIST KNOT

WHEEL BRUSHES

Diameter

RPM

Diameter

Diameter

Diameter

100

11000

60/65/75

100

100

115

11000

60/65/75

100/115

115

125

10000

60/65/75

115

125

150

9300

75

-

-

180

8500

80/100

-

150/180

230

6500

125/150

-

200

MAXIMUM PERIPHERAL SPEED WHEEL BRUSHES

Diameter (mm)

Max RPM

80

10000

100

8000

125

6000

150

6000

180

6000

200

4500

250

3600

250 - 1 row

3500

300

3000

BRUSHING PRESSURE

• The tips of a wire brush do the work. Operate the brush with the lightest

pressure so only the tips of the wire come in contact with the work.

• If heavy pressure is used, wires will be over stressed, resulting

in a wiping action, and if this is continued, the life of the brush will be

shortened due to wire fatigue.

• Apply the work to the face of the brush ensuring as much of the brush

face as possible is in full contact. Applying the work to the side or edge of

the brushing tool will result in wire breakage and shortened brush life.

• Reversing the wheel brush rotation periodically will tend

to increase the life of the brush. This results in the sharpening

of the wire tips or ends, ensuring faster cutting action.

Crimped wire

Twist Knotted

STEEL

30m/s

35-40m/s

NON FERROUS

18-20m/s

PLASTIC

15m/s

The maximum RPM ratings are

safety ratings not recommended

operating speeds. The optimum

operating speed is determined

by the application and in most

cases lower operating speeds will

prove more efficient and achieve

the best result. As a general guide

we recommend the following

peripheral speeds when working

on the materials listed with:

MAXIMUM PERIPHERAL SPEED

SHAFT MOUNTED WIRE BRUSHES

Diameter (mm)

Max RPM

20

20000

30

20000

40

18000

50

15000

60

15000

70

15000

80

12000