FLEXBRITE

NON-WOVEN

ABRASIVES

174

FLAP WHEELS & BRUSHES

Flexovit Flap Wheels and brushes are available in a wide range of abrasives, grits and densities. Flap wheels

and brushes are used in many industries, from metal working to wood working. Flexbrite Flap Wheels are suitable

for a variety of applications, from surface cleaning through to satin finishing and light deburring. The different

densities make the products very versatile: from soft densities that give cushioning actions ideal for use on

uneven or irregular surfaces, to hard densities ideal for cleaning and finishing metal.

FLAP BRUSHES

Advantages:

Flexbrite brushes have different densities and are interleaved with coated abrasives giving

significant benefits over other types of abrasives.

FLAP WHEELS

Advantages:

Flexbrite Flap Wheels not only works well on flat areas, but is also ideal for use in finishing

operations on uneven surfaces. They are especially suitable where they need to adjust to the surface and give

a uniform finish. When used on most metals, A/O (Aluminium Oxide) Flap Wheels will produce a long line scratch

pattern with a dull satin, matt type, finish. The SIC (Silicon Carbide) Flap Wheels will produce a long scratch finish

with a semibright, matt type, finish.

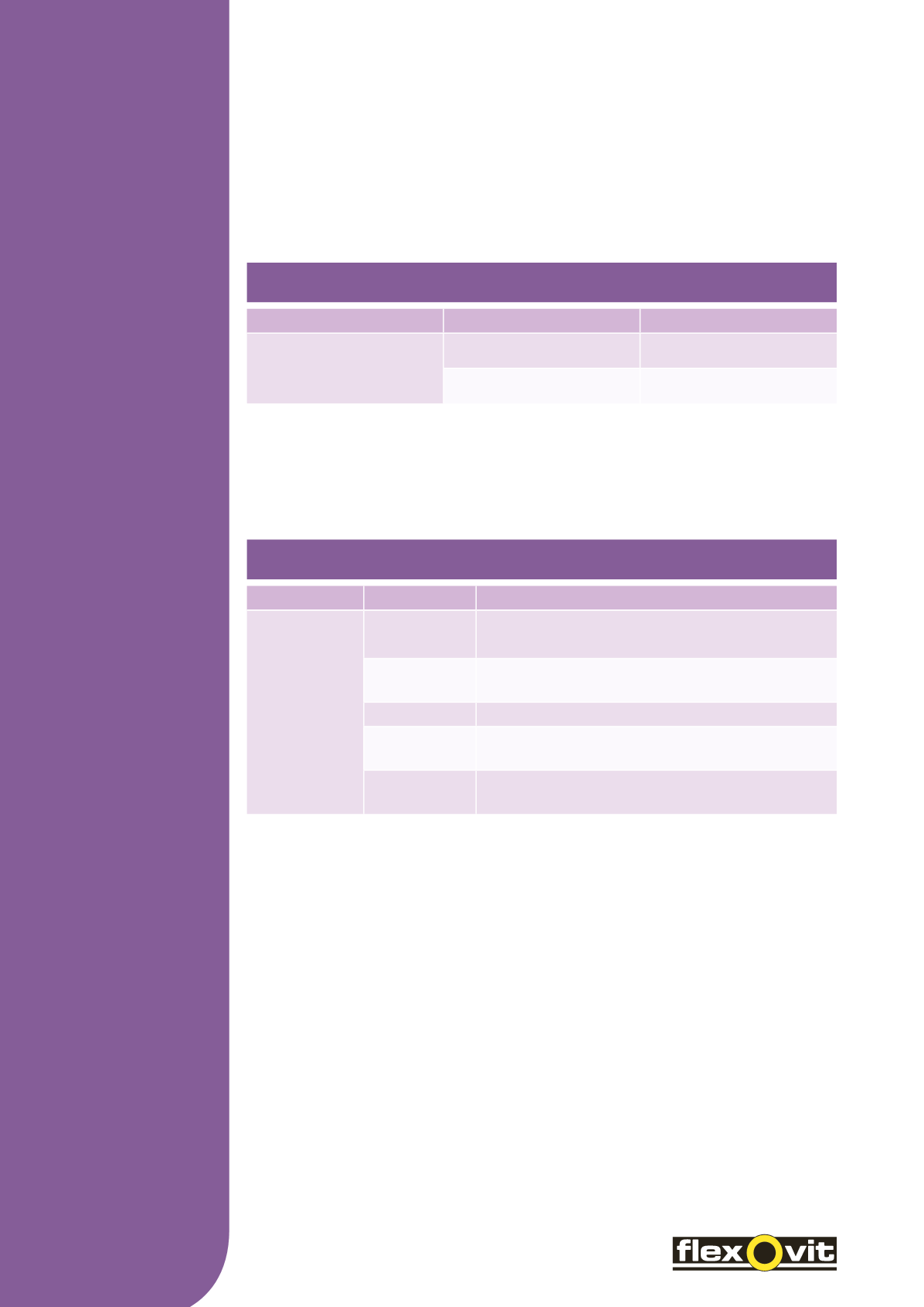

APPLICATION FLAP WHEELS

Type

Industry

Application

Flap Wheels

all densities

Architectural

hardware

Finishing brass aluminium & steel

/ Sateen finishing

Cast Iron

Removing old gasket materials on cylinder heads

of diesel engines

Automotive

Removing stonechip coating, paint & rust

Stainless Steel

fabricators

Weld blending /

Removing of imperfections / Blending spot welds

Stainless Steel

fabricators

Grain finishing on sheets

SELECTING THE RIGHT PRODUCT

Type

Industry

Application

Wide faced brushes

Strip metal

Cleaning / Finishing

Wood chip board

De-fuzzing