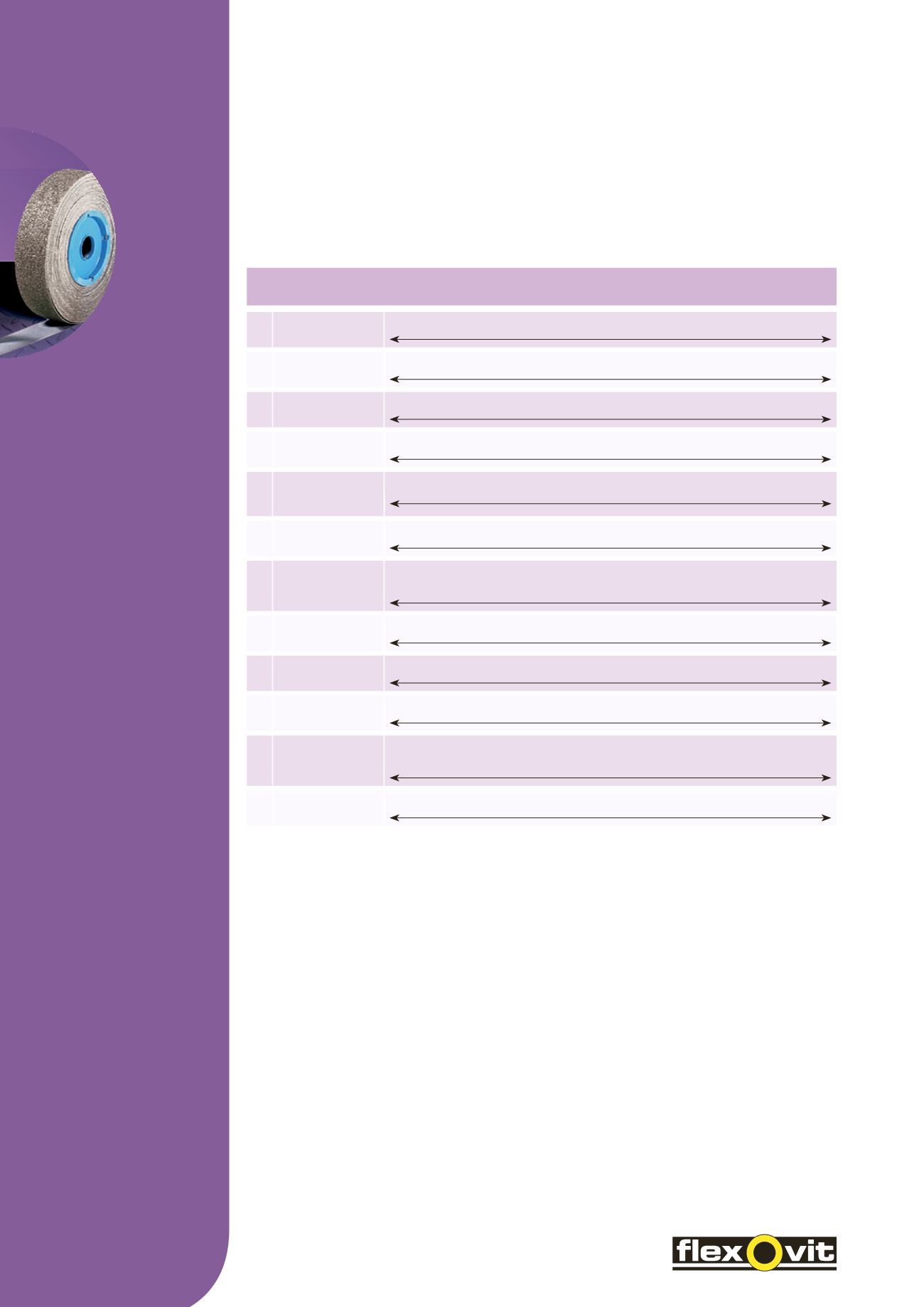

COATED

ABRASIVES

64

VARIABLE FACTOR

ROUGH SURFACE

HIGHER RA READING

SMOOTH SURFACE

LOWER RA READING

1. Grit Size

Coarse

Fine

2. C/A Product Condition

New

Used

3. Adhesive Bond

Resin

Resin/Glue

Glue

4. Coating Method

Open-Coated

Close-Coated

5. Product Flex

Single Linear

Double Triple

6.

Contact Wheel

Configuration

Serrated

Smooth

Composition

Wider Groove

Width Steel

Rubber

Wider

Width Canvas

Diameter

Smaller

Larger

7. Belt Speed

Slower

Faster

8. Grinding Aid

Dry

Water

Oil Solubles Staight Oils

Grease

9.

Abrasive

Mineral Type

Zirconia

Alumina

Ceramic

Aluminium

Oxide

Silicon

Carbide

Emery

10. Workpiece Hardness

Softer

Harder

SURFACE FINISH & GRINDING EFFICIENCY VARIABLES

SURFACE FINISH VARIABLES

Changes in any one of many factors can affect the surface finish generated by a product. The purpose of this

chart is to show the effect on surface finish by changes in single factors of product specifications. Arrows have

been used to signify the trend direction. The length of the arrows has no significance as the effect of each variable

factor will not be the same. The chart is meant to be general in nature and to show direction or trend.

TECHNICAL INFORMATION