COATED

ABRASIVES

65

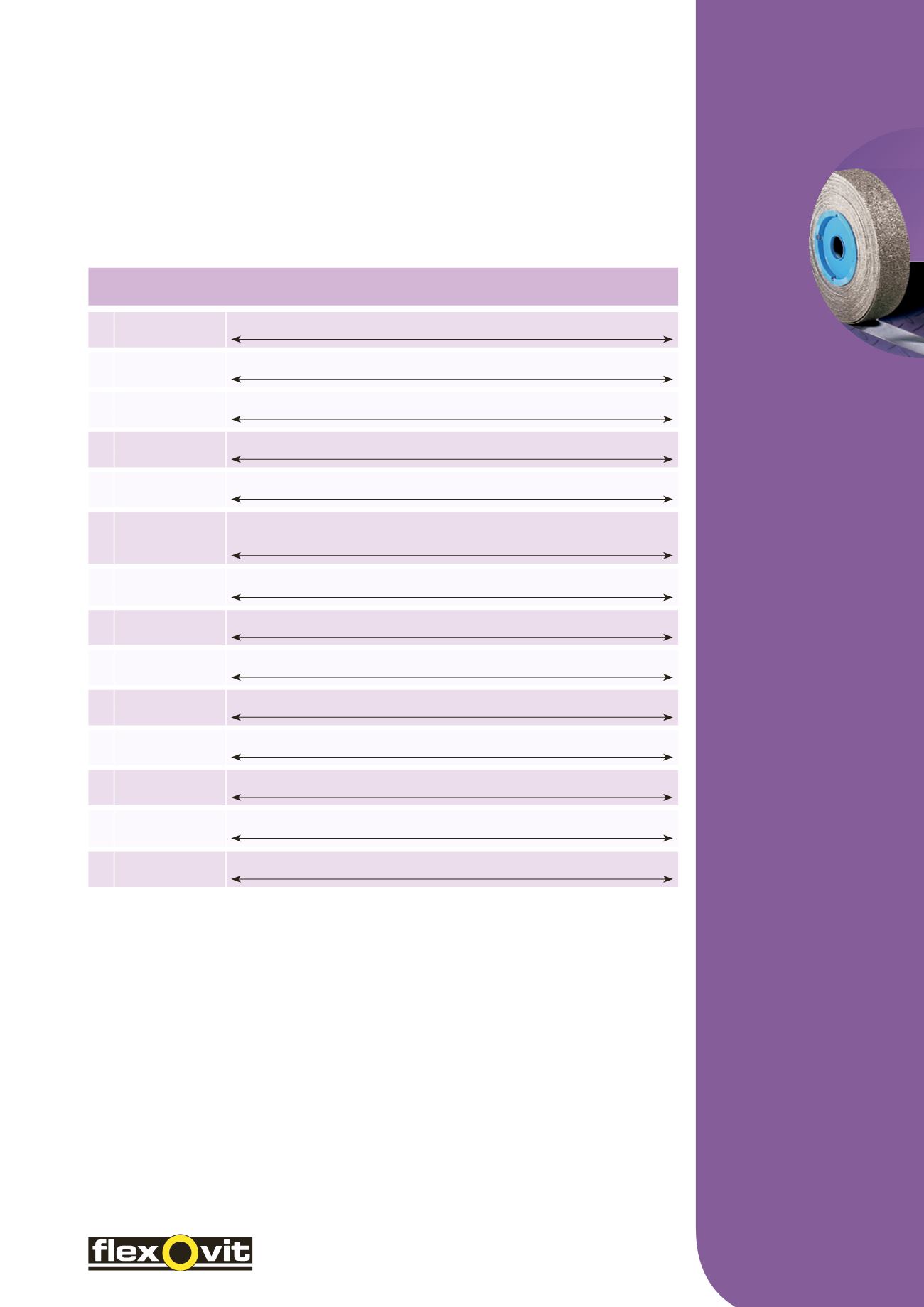

CUTTING EFFICIENCY OF COATED ABRASIVE PRODUCTS

Although general in nature, this chart can serve as a useful guide as to what effect a change in a single given

factor in the specification will have on the cutting efficiency of coated abrasive products. Arrows have been

used to signify the trend direction. The length of arrows has no significance. Some important machine and setup

parameters have also been included since they do have significant impact on product performance.

VARIABLE FACTOR

MORE AGGRESSIVE

BETTER CUT

LESS AGGRESSIVE

LOWER CUT

1.

Workpiece

Feed Speed

Slower

Faster

2.

C/A Belt

Speed (m/s)

Slower

Faster

3.

Abrasive Product

Condition

New

Used

4. Grit Size

Coarse

Fine

5. Product Durability

Fibre

Cloth

Paper

6.

Abrasive

Mineral Type

Zirconia

Alumina

Ceramic Aluminium Oxide

Silicon

Carbide

Emery

7. Adhesive Bond

Resin

Resin/Glue

Glue

8. Coating Method

Close-Coated

Open-Coated

9.

Contact Wheel

Configuration

Serrated

Smooth

Composition

Steel

Rubber

Canvas

Diameter

Smaller

Larger

10. Pressure

High

Low

11. Grinding Aid

Oil

Soluble Oil

Water

Dry

12. Workpiece Hardness

Softer

Harder