BONDED

ABRASIVES

229

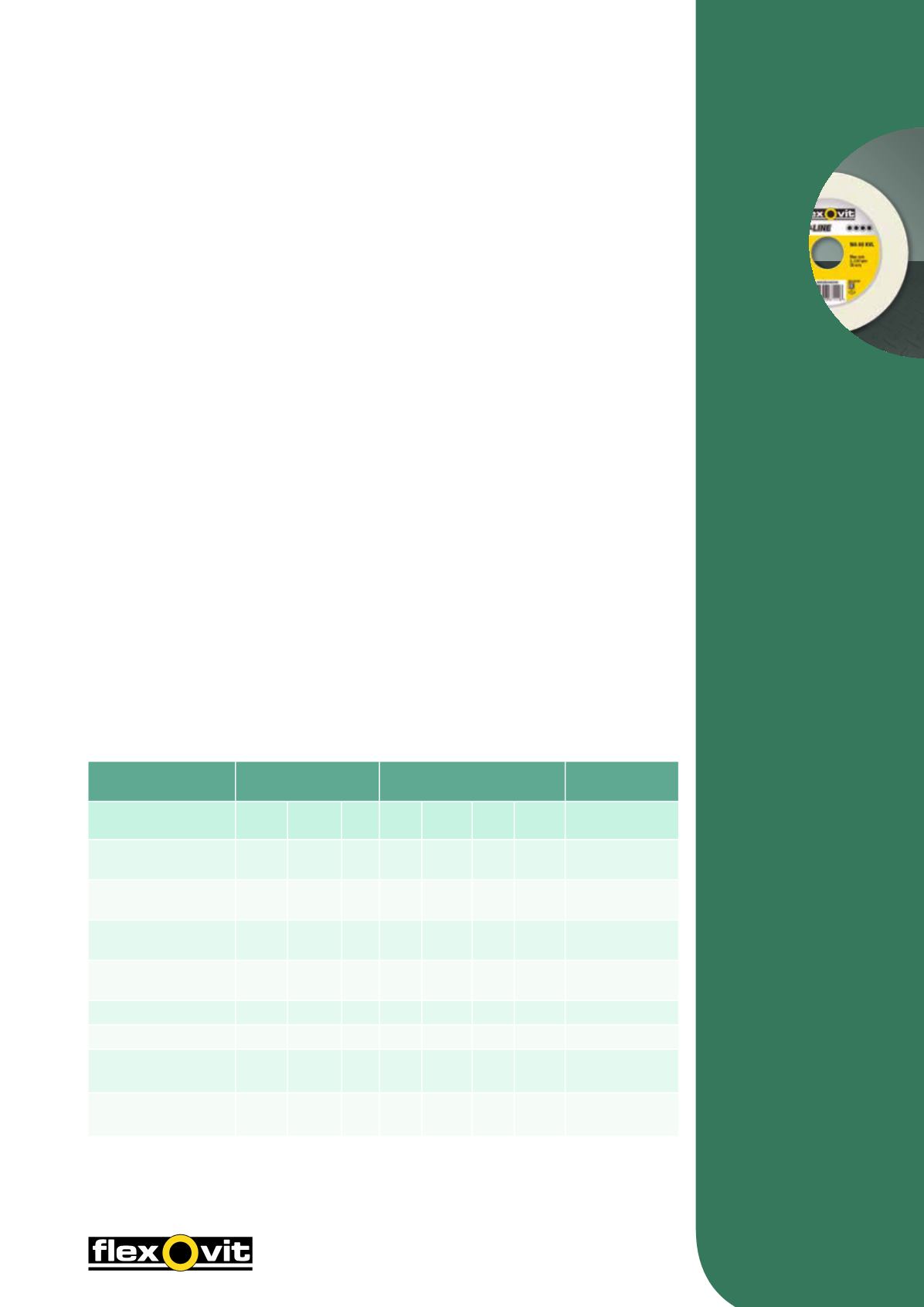

Abrasive Type Size of the Abrasive

Grain

Hardness of the Bond Type of Bond

Coarse Medium Fine Soft

Med Hard

Extra

hard

WA = Alumunium

Oxide

C

M F Soft Med Hard VHard

V = Vitrified

73A = Ceramic

Abrasive

12

46 150 E

J

N S

B = Resinoid

48A = Semi-friable

Aluminium Oxide

14

54 180 F

K O T

BF = Resinoid

reinforced

A = Aluminium

Oxide

16

60 220 G L

P

U

E = Shellac

GC = Silicon Carbide

20

80 240 H M Q V

R = Rubber

C = Silicon Carbide

24 100 280 I

R W

41A = Aluminium

Oxide

30 120

X

44A = Aluminium

Oxide

36

WHAT IS A GRINDING WHEEL?

A grinding wheel is a precision tool with thousands of cutting points. It consists of abrasive grains held in a matrix

of bond and separated by pores. The abrasive grains are the cutting points while the purpose of the bond is to

hold the individual grains together. The pores (hollow spaces between adjacent abrasive grains and the bond)

serve to provide clearance for coolant penetration and metal chips removed in the grinding process.

When the wheel is rotated at grinding speed and applied to the workpiece, the abrasive grains cut the material

that is being ground, removing the material in small chips.

Under the action of the forces imposed during grinding the abrasive cutting points are worn flat, resulting in

the points becoming blunt. This causes an increase in friction, heat build up and the forces imposed on the wheel.

The increase in grinding forces causes either the abrasive to fracture, exposing new cutting edges, or fractures

the bond bridges holding the abrasive grains. In the latter case fresh abrasive grains are exposed to cut

the workpiece.

In normal vitrified grinding applications the wheel has to be dressed.

By varying the properties of the abrasive, the type of bond, the make-up of the wheel, it is possible to produce

grinding wheels with a vast range of different grinding characteristics.

ABRASIVES

Modern synthetic abrasives allow accurate control over the physical properties and form of the abrasive grain.

This helps to ensure that grinding wheels can be manufactured with consistent cutting properties.

Flexovit offers a comprehensive selection of abrasive types to provide a wide range of specific grinding

characteristics. This is necessary for maximum efficiency in the large variety of operations demanded by

the industry today.

Abrasive Grain Size

The grain or grit size is most important in determining a wheel’s ability to achieve the required surface finish

and remove stock. The size is designated by a number which increases as grain size decreases. For example

10 grit has a median size of about 2,0mm and 60 grit 0,25mm.

Standard sizes are used in all Flexovit wheels as specified in the European Standards laid down by FEPA.

An ideal grinding abrasive has the ability to stay sharp with minimum point dulling, and when dulling begins

it fractures revealing new sharp cutting edges. Abrasive grains used in the manufacture of bonded abrasives

come in three main categories: